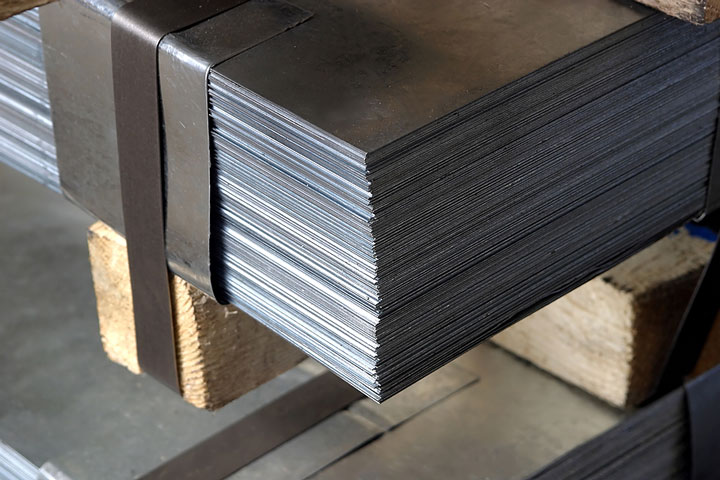

So you’ve got a project looming on the horizon and you’ve come to the realisation that (either out of choice or necessity) you need stainless steel sheet. Before we jump straight into the why’s and wherefore’s tacmeds.com of sheet metal purchasing, we thought that it would be a good idea to dispel some of the myths surrounding it. Firstly stainless steel sheeting in any grade is not entirely rust-proof or stain proof and in some cases it will corrode. Therefore it’s important to bear this in mind before making a purchase. Having said that, stainless steel sheeting is perfectly sufficient for ‘most’ home and commercial applications. There are also further misconceptions about what a sheet actually entails. To make it simple, if you need a steel metal product over 3mm thick, then it isn’t a sheet you need. Anything under this, but over 0.4mm thick then yes it’s a sheet.

So now we’ve busted a few myths and given you some pointers, you’re really only left with three considerations: these are grade, size, and finish. Let’s take a brief look at these in turn.

Grade

For most people the choice of two grades will just about cover any project and these are grade 304 and 316 steel sheeting. Both have many of the same characteristics in that they’re tough, versatile and easily fabricated with excellent welding characteristics. However 316 grade has one main advantage that its counterpart doesn’t. It has a higher resistance to corrosion, (chloride and salt water in particular) and this is why it’s more commonly referred to as ‘marine grade’ steel. It’s also often used to make up commercial kitchens as it’s perfect for food preparation areas. Because of these advantages, 316 grade is generally more expensive than 304 grade, so it might be worth using 304 grade in areas that aren’t prone to salt water or chloride to keep within your budget.

Size

Stainless steel sheets are normally somewhere between 2.8mm and 0.4mm in thickness. Over 3mm and you’d probably be referring to a plate. Conversely, less than 0.4mm and you’ll be needing a foil instead. Generally speaking there are only really two ‘off-the-shelf’ sizes of steel sheeting and these are 1000mm x2000mm and 2500mm x 1250mm. That said, if you need a specific length then any half-decent fabricator can and will cut it to exactly the right proportions for you in no time at all.

Finish

The Steel fabrication process allows us to develop, shape and roll steel into just about any structure and finish, but to keep things easy, here are the most common finishes and the main ones that you’re likely to need. These are brushed steel, satin finish and mirror polishing. Depending upon the look you want to create, will depend upon the finish you need.

So there you have it. Some important tips on how to buy the right stainless steel sheeting. If you’re still not sure, then experienced fabricators such as Metro Steel can help. Why not contact us on 07 3204 1000 and we’ll give you peace-of-mind.

Working Hours - Mon – Fri 7:00 AM – 4:00 PM

Working Hours - Mon – Fri 7:00 AM – 4:00 PM Talk to an Expert (07) 3204 1000

Talk to an Expert (07) 3204 1000