Powder coating is a cutting-edge finishing technique designed to enhance and protect metal products. Unlike traditional liquid paint, powder coating uses an electrostatically charged dry powder that adheres to metal surfaces and cures into a durable, even layer under heat. This process creates a robust, long-lasting finish that is both aesthetically pleasing and highly functional. If you’re considering ways to improve the resilience and appearance of your metal products, powder coating offers a compelling solution, combining durability, customisation, and environmental friendliness.

At Metro Steel, we are passionate about delivering top-tier solutions that elevate the quality and longevity of your metal products. Powder coating is a standout method for finishing metal and in this blog, we’ll explore why it’s an excellent choice for your fabrication needs.

Understanding Powder Coating

What Is Powder Coating?

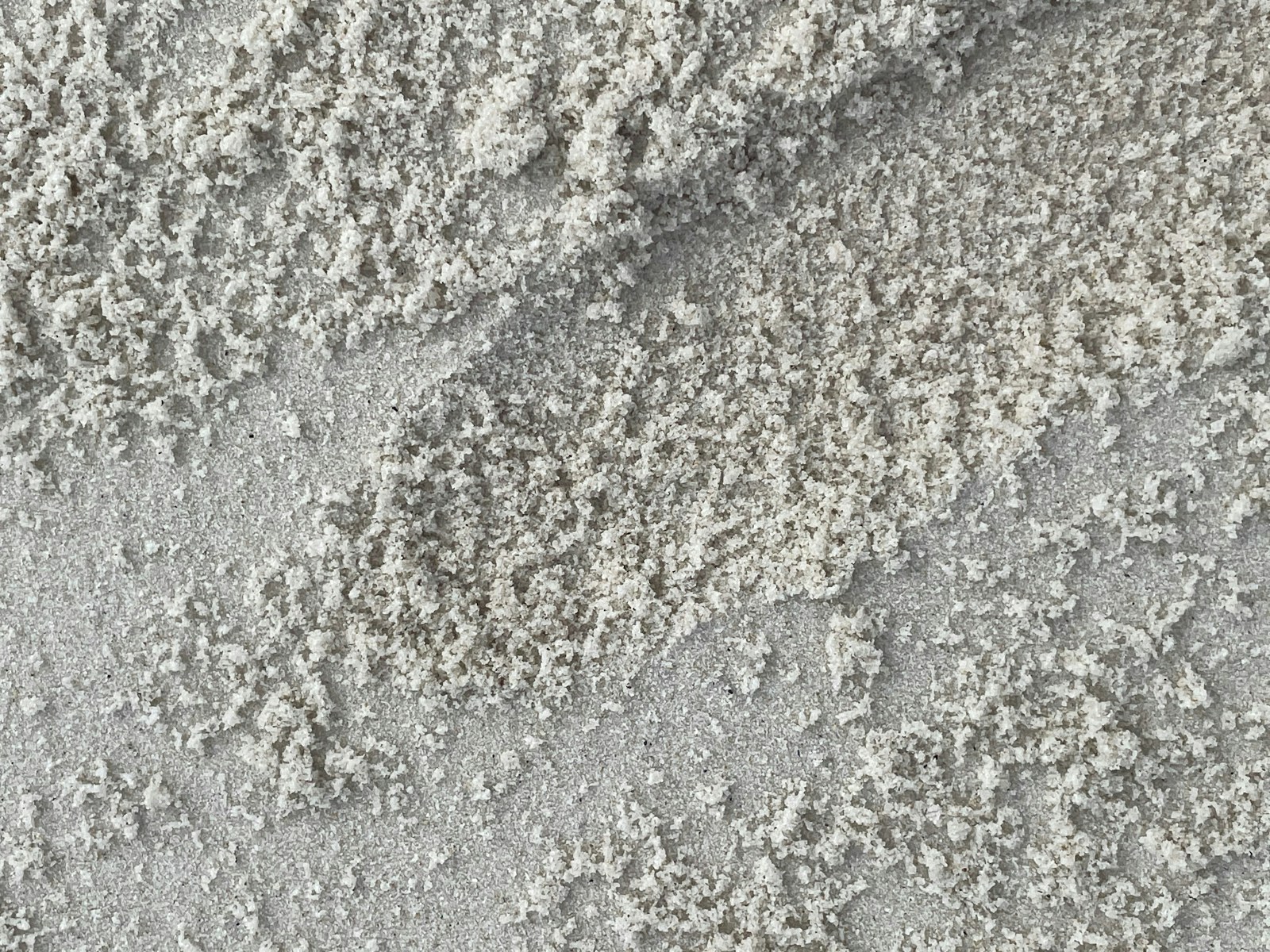

Powder coating is a state-of-the-art finishing technique that uses a dry, powdered material to coat surfaces. Unlike liquid paints that rely on solvents, powder coating utilises finely ground particles of pigment and resin. These particles are electrically charged and applied to the metal surface, creating a strong and reliable bond. Once the powder is applied, the coated item is heated in a curing oven, melting the powder and forming a robust, uniform finish.

The Powder Coating Process Explained

The process of powder coating is straightforward yet highly effective. Here’s a step-by-step breakdown:

- Preparation: The metal surface is cleaned thoroughly to remove dirt, oils and debris. This step ensures optimal adhesion of the powder.

- Application: The powdered coating material is applied using an electrostatic spray gun. The charged particles cling to the grounded metal surface, covering it evenly.

- Curing: The coated metal is placed in a curing oven, where high heat melts and bonds the powder to the surface, forming a smooth, durable layer.

- Inspection: The finished product undergoes a quality check to ensure consistency and perfection.

The Key Benefits of Powder Coating

Exceptional Durability

Powder coating is celebrated for its exceptional durability and robust nature. The cured finish forms a protective barrier against scratches, chipping and general wear and tear, significantly extending the lifespan of metal products. Whether it’s a heavily used industrial component or a decorative item, powder-coated surfaces stay intact under demanding conditions.

Superior Finish Quality

One of the standout features of powder coating is the flawless, uniform finish it delivers. Unlike liquid paint, it doesn’t leave brush marks or uneven surfaces. The result is a smooth, professional appearance that enhances the aesthetic value of your metal products.

Environmentally Friendly Choice

Powder coating is a sustainable option for metal finishing. Since it doesn’t require solvents, it emits negligible volatile organic compounds (VOCs), making it safer for the environment. Additionally, any excess powder can be recycled, reducing waste and minimising the overall environmental footprint.

Cost-Effective Solution

While the upfront cost of powder coating may exceed that of traditional painting, its lasting resilience makes it a cost-effective choice over time. Powder-coated products require less maintenance, resist damage effectively and don’t need frequent touch-ups or replacements.

Wide Range of Colours and Textures

Powder coating offers endless possibilities when it comes to customisation. You can choose from a vast array of colours, textures and finishes, including glossy, matte, metallic and even special effects. This versatility ensures that your products align perfectly with your aesthetic or functional needs.

Enhanced Corrosion Resistance

Powder coating acts as a formidable barrier against rust and corrosion. It’s especially beneficial for metal products exposed to moisture, chemicals, or harsh weather conditions, as it keeps the underlying material protected and intact.

UV and Fade Resistance

Sunlight exposure often leads to colour fading, but powder coating maintains its vibrancy for the long haul. Its UV-resistant properties help maintain vibrancy, ensuring that your products look as good as new for years to come.

Common Applications of Powder Coating

Industrial Metal Products

Powder coating is extensively employed across industries for machinery, equipment, and structural elements. Its durability ensures these critical items perform reliably, even in tough environments.

Automotive and Transportation

Whether for car components or bicycles, powder coating delivers a tough yet visually appealing finish capable of enduring the challenges of daily use. Its corrosion resistance also makes it ideal for outdoor applications.

Home and Garden

Powder coating is popular for furniture, fencing and decorative pieces. Its customisation options and weather resistance make it a go-to choice for outdoor and indoor items alike.

Maintaining Powder Coated Metal Products

Cleaning Tips

One of the many advantages of powder-coated surfaces is their ease of maintenance. Regular maintenance, including routine cleaning, is key to preserving their fresh and vibrant appearance. A simple wipe-down with a soft cloth, mild detergent and water is sufficient to remove dirt and grime. Rinse thoroughly with clean water to avoid leaving any residue and allow the surface to air dry or use a soft cloth to pat it dry.

It’s important to avoid abrasive cleaners or harsh chemicals, as these can damage the powder-coated finish, dulling its sheen and reducing its lifespan. Similarly, steer clear of scouring pads or steel wool, which can scratch the surface. Instead, opt for non-abrasive cleaning tools to maintain the integrity of the coating.

Avoiding Damage

Powder-coated surfaces are highly durable, but they aren’t invincible. To preserve their pristine condition, handle them with care. During transport or storage, use protective padding to prevent scratches and chips caused by accidental impacts. If you need to stack or move powder-coated items, ensure that the surfaces don’t rub against each other.

Additionally, avoid dragging heavy or sharp objects across powder-coated surfaces, as this can cause unsightly scratches. For outdoor items like garden furniture or fencing, regularly inspect for signs of wear or damage and address minor issues promptly to prevent them from escalating. With proper care, powder-coated products will retain their durability and aesthetic appeal for years to come.

Elevate Your Metal Products with Powder Coating from Metro Steel

If you’re ready to transform your metal products, powder coating is the way to go. At Metro Steel, we pride ourselves on delivering finishes that combine durability, beauty and functionality. With our expertise and commitment to quality, you can trust us to meet your unique requirements. Let us help you enhance your products with a finish that lasts. Contact us today to learn more!

Powder coating offers unmatched benefits, from its exceptional durability to its environmentally friendly nature. Whether you’re looking to protect industrial equipment, customise furniture, or extend the lifespan of metal components, powder coating delivers. At Metro Steel, we’re dedicated to providing powder coating solutions that exceed expectations. Reach out to us today to discover how we can help elevate your metal products!

Working Hours - Mon – Fri 7:00 AM – 4:00 PM

Working Hours - Mon – Fri 7:00 AM – 4:00 PM Talk to an Expert (07) 3204 1000

Talk to an Expert (07) 3204 1000